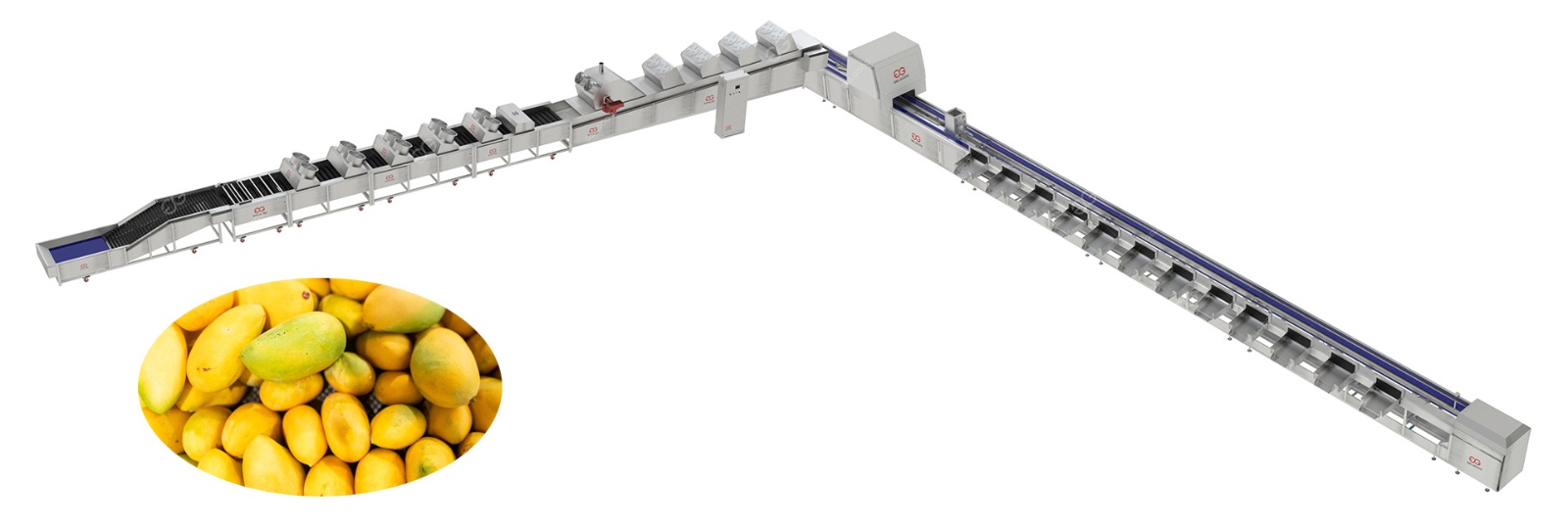

The mango processing line optimizes the mango processing process through automated and intelligent design, providing enterprises with efficient, hygienic and reliable solutions from washing, waxing, air drying to grading.

Importance of Mango Washing Grading Line

As a high-value tropical fruit, mango has extremely high requirements for hygiene, efficiency and quality during its processing. Traditional manual washing and sorting methods are not only inefficient, but also difficult to ensure product consistency and safety. The mango processing plant optimizes the mango processing through automated and intelligent design, providing enterprises with efficient, hygienic and reliable solutions from washing, waxing, air drying to grading.

Manufacturing Process of Mango Processing Plant

The mango washing line adopts a modular design, covering the complete processing process from raw materials to finished products:

Lifting: The mango is transported from the raw material area to the washing line through a hoist to reduce manual handling and improve efficiency.

Washing: Bubble washing and high-pressure spraying technology are used to thoroughly remove dirt, pesticide residues and microorganisms on the surface of mangoes to ensure hygiene and safety.

Blanching: Mangoes are heat treated for a short time using temperature-controlled blanching equipment to kill surface bacteria while maintaining the freshness and taste of the flesh.

Waxing: After washing, the mango enters the waxing stage, and food-grade fruit wax is evenly sprayed to improve the gloss of the appearance and extend the shelf life.

Air drying: Through the efficient air drying system, the moisture on the surface of the mango is quickly removed to avoid secondary pollution and prepare for subsequent grading and packaging.

Grading (weight): A high-precision electronic weighing system is used to automatically grade mangoes according to their weight to ensure consistent product specifications and meet market demand.

01

Fully automated operation: reduce manual intervention,improve production efficiency

02

Made of food-grade SUS and supports ozone sterilization to ensure food safety

03

Equipped with water circulation system to reduce water and energy consumption, lower operating costs.

04

High-precision weighing system ensures accurate mango grading

05

Customize equipment specifications and functions according to customer needs to adapt to production lines.

06

Provide installation and commissioning, technical training and lifelong maintenance services to ensure stable operation.

Login

Get product information

Contact us