GELGOOG Cassava Starch Processing Machine is one of top Equipment Manufacturer For Starch From Cassava in China. We specialize in Cassava Starch Production line exporting and manufacturering. The complete set of Cassava Starch Machinery including: Cassava Washer, Cassava Crusher, Cassava Filter, Cassava Starch Vacuum Sifter, Cassava Starch Air Flow Drier, Cassava Starch Centrifugal, Cassava Starch Hydrocyclone, Casava Starch Drying System, Cassava Starch Automatic Packer, etc.

Cassava starch processing machinery is with wide applications in various field. GELGOOG Cassava starch processing machine inherits all the merits of the original model, enhanced by new technology. Compared with other Cassava starch processing machine, our Cassava starch processing machine enjoys many advantages including: more reasonable structure, more compact appearance, smoother operating, higher efficiency and is easy to operate and maintain. Cassava starch processing machinery has wide adoptablity, is an ideal Cassava starch processing machinery for you to convert into production. We are one of the most famous Cassava starch processing machine exporters in China. We have been supplying a whole set of Cassava starch processing machine for overseas customers. We would like to provide maximun customer satisfaction at lowest possible cost and best after-sale service.

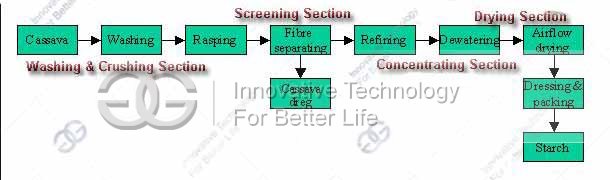

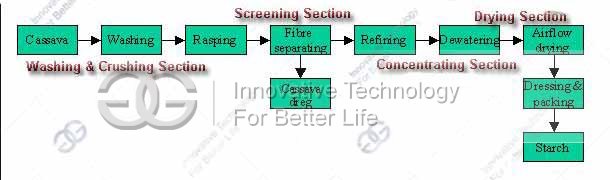

The Processing of Cassava Starch:

* Preparation of Root

The Stage starts removing sand & soil, peeling the skin, than washing intensively until the root are blank.

* Extraction of starch

The main stage to separate fiber from starch milk.The starch milk is concentrate by separators to 40% starch content, then filtered in dewarterring centrifuge to give a wet starch in powder form, containing 35-38% water.

* Rasping of Root

At this stage they are visually inspected and the wooden tips are chopped off manually,then rasping to release absolutely starch from root tissue, makes a mixture of starch and fiber in water,loosing sufficient for pumping.

* Drying of starch

The stage is dried to 12.5% humidity in flash dryer,to be finally packed into bags different sizes & weight of the finest quality starch available to meet customers satisfaction.

Your Position:

Your Position:

E-Mailggjx@gelgoog.com

E-Mailggjx@gelgoog.com Contact0086-18537181190

Contact0086-18537181190 Whatsapp0086-18537181190

Whatsapp0086-18537181190 TOP

TOP