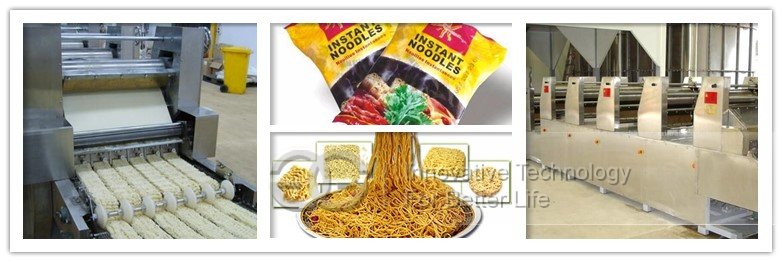

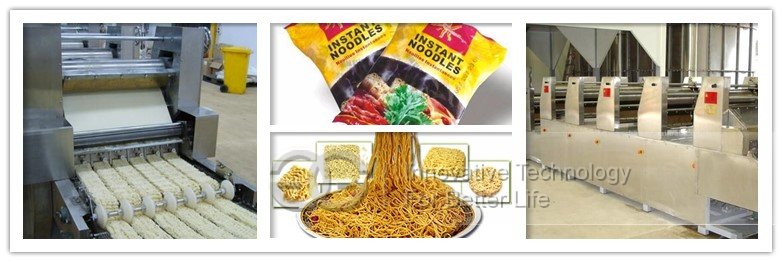

Fried instant noodle machine is researched and developed by GELGOOG company independently so as to meet the market demands, with the advantages of similar equipment at home and abroad, the product is a leading fried instant noodle production equipment, which is elaborately designed and manufactured by experts with rich wisdom and experience, and it is perfect carrier of mechanical-electrical integration in the whole production line.

Advanced technologies of fried instant noodle machine:

1, The closed-loop speed control system, consisting of speed feedback control and high-precision pulse coder, is designed to perform synchronous control on the whole production line, and it is featured of easy adjustment and high precision synchronization.

2, It takes the programmable logic controller (PLC) as the process center, and perform automatic control on the process, and the motors on most single machines adopt frequency speed control.

Automatic instant noodle processing line is new generation development which developed by our company based on similar productions from overseas and domestic market.

Main machines of this plant are dough mixer, curing machine, continuous rolling machine, cooking machine, cutting and folding machine, frying machine, cooling machine, and packing machine.

It can produce30, 60, 80, 100 or 160, 200 thousand bags of instant noodles every shift.

Main advantages of the total instant noodle production line:

The whole production line is well designed with sound shaping, applicability and safety.

This plant is highly automatic, convenient, low energy consumption and less space occupation, invest on this line is 10% of cost on large processing line,

The corrugated instant noodle produced by this line is strength, smooth and transparent.

Your Position:

Your Position:

E-Mailggjx@gelgoog.com

E-Mailggjx@gelgoog.com Contact0086-18537181190

Contact0086-18537181190 Whatsapp0086-18537181190

Whatsapp0086-18537181190 TOP

TOP