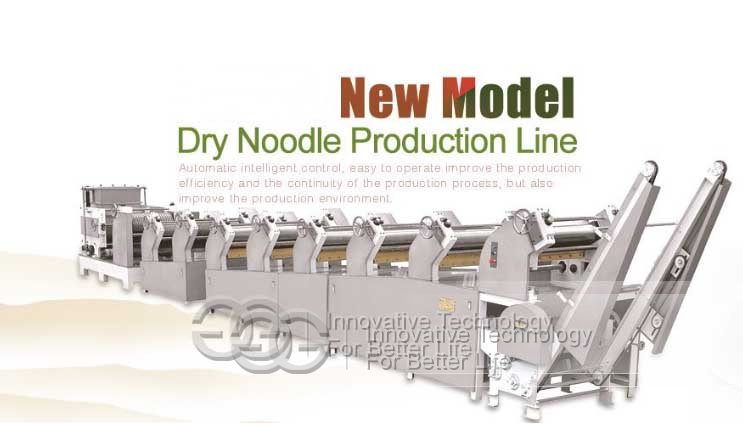

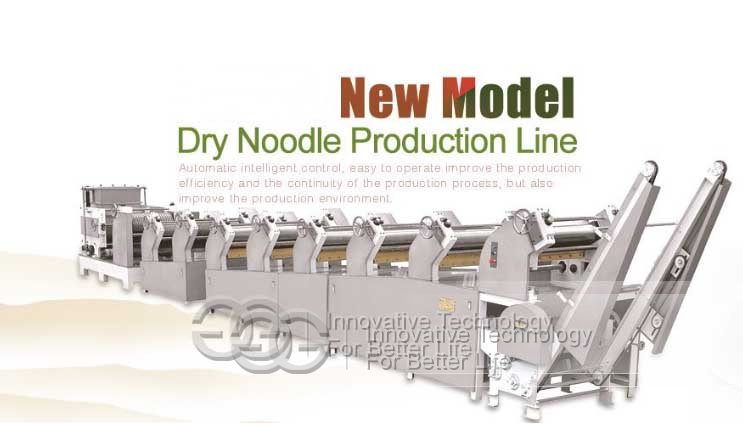

Stick Noodles or Dry Noodles Production Line

Stick Noodles or Dry Noodles Production Line of Henan GELGOOG Machinery is equipped with excellent equipment, and the whole process is highly automated, it can be operated, with good production continuity, excellent product quality and high rate of the finished product, and low energy consumption. This noodles production line adopts vacuum mixing technology and photoelectric control technology, as a symbol of the third generation Hanging noodles production line, representing the advanced level of the domestic industry.

1. Power supply system

By means of automatic feeding system, the raw materials are transported to the metering device in a certain way. The whole system of the powder feeding system, the work of the signal to achieve automatic control. This not only greatly reduces the labor intensity, improve the production efficiency and the continuity of the production process, but also improve the production environment.

2. Dough mixing, curing and rolling

Dough mixing technology includes brine mixing plant, quantitative water supply device and two sets dough mixer machine. During the whole process, water supply is accurate, the system is good, the degree of automation is high, produces dough is with high quality. And the dough mixer adopts variable frequency double speed (high speed and low speed mix kneading), and adjustable speed, and time can be set according to the need of the process. All operation procedures and steps can be realized by PLC program automation control.

And the dough after 5-10 minutes after ripening, will be automatically fed to compound pressing machine, and rolling into the required thickness of the sheet, after cutting, rod, shelves into the drying chamber. The whole process through the photoelectric switch and frequency converter to achieve automatic intelligent control, easy to operate. And the equipment supporting reasonable design, reliable quality, high safety, good effect of rolling equipment and rolling process.

3. Drying

The noodles into the chamber, cut by cutting machine, the wet noodle can be through the wet noodle returning device continuously and uniformly conveyed to the uniaxial U curing machine, which can reduce the number of workers and reduce labor intensity, but also achieve wet noodle's timely back. To avoid the long time interval and lead to the loss of water, thus affecting the effect of technology and product quality.

4. Cutting and packing

Stick noodles are cut by cutting machine, and the finished noodles will be transported to the weighing and packing machine through noodles conveying equipment; broken noodle will be smashed to pieces dry noodle breaking device for the preliminary broken, then transported to the collecting system broken by wind mill head, crushing machine can import powder according to the proportion of return add powder supply system.

Your Position:

Your Position:

E-Mailggjx@gelgoog.com

E-Mailggjx@gelgoog.com Contact0086-18537181190

Contact0086-18537181190 Whatsapp0086-18537181190

Whatsapp0086-18537181190 TOP

TOP