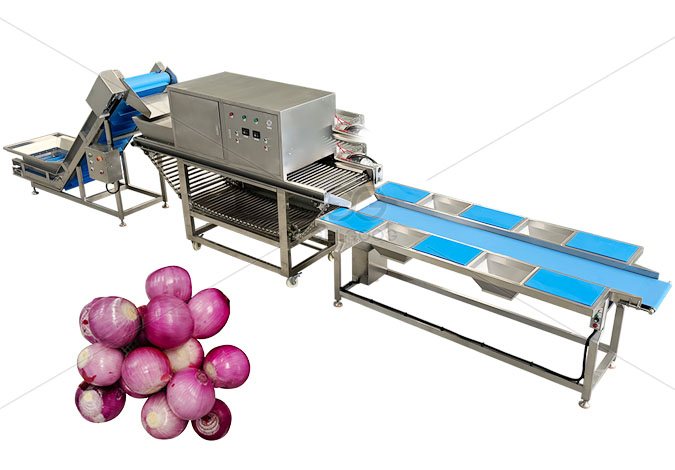

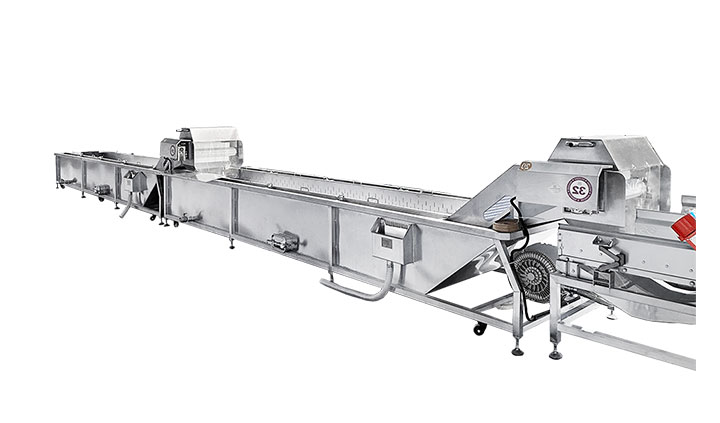

Factory Inspection-Bangladesh Customers Inspected Avocado Mango Washing Grading Line

Recently, a Bangladeshi customer visited our factory, from equipment operation to finished, gave a high evaluation of the avocado mango washing line quality and processing effect.

Mar 06, 2025

Fruit Vegetable Processing

Fruit Vegetable Processing Nuts Processing Solution

Nuts Processing Solution Pastry Processing Solution

Pastry Processing Solution