Chili is a vegetable condiment that is often eaten in daily life. The production of dried chili in industry is mainly to use a heat pump dryer. GLEGOOG machinery will introduce the drying method and technology of the chili pepper dryer.

GELGOOG also offer the complete set of chili powder production line

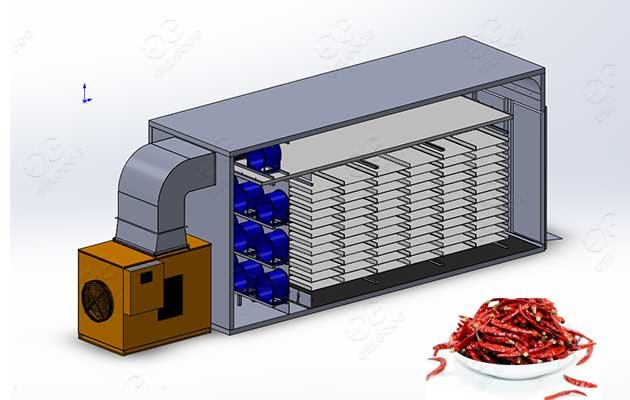

About Chili Drying Equipment:

Chili drying equipment is a kind of heat pump dryer, which uses the principle of reverse Carnot cycle to absorb heat from the air and transfer it to the room, thereby increasing the temperature in the drying room, and cooperating with fans and other equipment to achieve drying of materials. The heat pump is mainly composed of condenser-compressor-throttle valve-condenser-compressor and other devices to form a circulating system.

Precautions for drying chili

※ Drying temperature parameters: The value of the hot air temperature for drying peppers determines the drying quality and efficiency of the peppers, so the needs of the peppers need to test the drying quality and efficiency of the ingredients of different varieties of peppers at various temperatures. , To determine the specific hot pepper drying temperature and other parameter settings. It should be noted that since pepper contains more than ten kinds of main nutrients, and some ingredients are easily lost and destroyed at high temperature, in order not to reduce the nutritional content, it is not appropriate to choose a higher hot air temperature.

※ The moisture content and humidity control: The key to controlling pepper drying is moisture. Normally, the moisture content of dried peppers is about 14%. If the moisture is too high, it is easy to mold and deteriorate, and if the moisture is too low, it is easy to break. Therefore, the moisture control should be appropriate. . At present, the drying method is mostly used to measure the moisture content of peppers. At present, the most widely used method is the halogen rapid moisture analyzer. It is easy to operate and fast in test speed. It is widely used in the field of moisture detection.

Pay attention to the stacking thickness of peppers when using a pepper dryer to dry peppers. Generally, the stacking thickness of peppers is 25-20 cm. The stacking thickness of peppers is too thin. Although the air permeability is good, the wind resistance is small, which is good for heat exchange. , But it will shorten the contact time between the pepper and the hot air, which will reduce the heat utilization rate. If the peppers are stacked too thickly, the resistance of hot air circulation will increase, and the hot air cannot penetrate the material layer, resulting in poor drying effect of the peppers and even problems that cannot be dried.

Application of Chili Heat Pump Dryer:

Chili drying machine is with wide application, which can be used to process fruit chips, apple chips, mango, pineapple, mushroom, chili, ginger, garlic, onion, moringa leaves, etc. GELGOOG machinery has achieved thousands of successful cases at home and abroad in the field of automatic drying equipment, accumulated rich production experience, and possessed advanced automatic drying equipment design and manufacturing technology. Any interest, please contact us for more details.

Brand:GELGOOG

Brand:GELGOOG Capacity:Can be customized

Capacity:Can be customized WhatsApp: 008618537181190

WhatsApp: 008618537181190

E-Mailggjx@gelgoog.com

E-Mailggjx@gelgoog.com Contact0086-18537181190

Contact0086-18537181190 Whatsapp0086-18537181190

Whatsapp0086-18537181190 TOP

TOP