Kiwi fruit contains vitamin C, VA, VE and other vitamins and antioxidants. Dried kiwi fruit contains fruit acid, which can inhibit pigmentation, effectively dilute or even clear dark spots, and improve the balance of water and oil. Kiwi fruit is known as the king of natural vitamin C and the king of fruits. It can be eaten fresh, and it can also be dried in a kiwi fruit dryer.

Dried Kiwifruit Processing Steps:

Kiwi fruit selection→cleaning→rinsing→slicing→drying→finished product

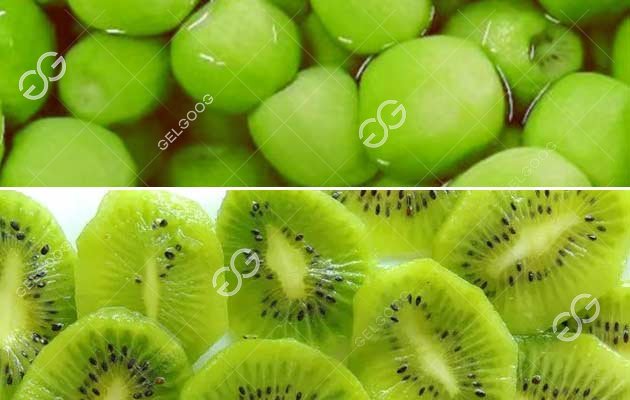

First clean the kiwi fruit, then use a machine or professional worker to peel off its rough peel, and cut the fruit into about 0.6cm thin slices. The entire process can now also be completed by a special assembly line machine operation, which improves the efficiency of processing and the accuracy of slicing.

1. Selecting of kiwifruit:

When the sugar content of kiwifruit reaches 7.5%-8% (i.e., eight mature), it will be collected immediately; sorting will be carried out at the time of purchase, and the deformed fruit, diseased fruit, and mildewed fruit will be removed. Then grading is given according to the size of the fruit, so that the product size of the kiwifruit after drying and processing is the same.

2. Peel and slice the kiwi:

Slice the peeled kiwi. In order to prevent oxidative discoloration of kiwifruit, the cut fruit should be stored in a 1%-2% salt solution.

3, kiwi blanching:

Put the cut fruit into boiling water for 2-3 minutes to kill the oxidase. After blanching, the kiwi fruit should be cooled with tap water quickly.

4. Kiwi pickled:

Drain the blanched kiwis and icing with sugar.

5. Kiwi drying temperature and time:

Remove and drain the sugar-boiled kiwifruit, put it on a stainless steel net, and send it to the drying room of the kiwifruit drying equipment for drying. The drying temperature is controlled at 65-70°C, and after

about 15 hours, the moisture content of the finished product reaches below 20%.

Advantages of GELGOOG kiwi fruit drying machine

Advantages of GELGOOG kiwi fruit drying machine:

★ The pollution-free oven in the production process adopts a multi-layer structure, which can realize continuous production in large quantities.

★ The processed materials are conveyed by multi-layer mobile stainless steel mesh belts with high production efficiency.

★ The heat source is a high-efficiency and energy-saving hot blast stove, and the hot air after combustion is converted into suitable low-temperature heat through a heat exchanger, which is economical and environmentally friendly.

★ Adopt lifting device, equipped with cooling layer and vibrating conveying device, the discharge temperature is low, which is conducive to timely packaging.

GELGOOG kiwi fruit drying machine can also be used to process other fruit and vegetables like apple, apricot, pineapple, banana, lemon, seaweed, date, leaves, mango, mushroom, chili, ginger, garlic, onion, etc.

Brand:GELGOOG

Brand:GELGOOG Capacity:Can be customized

Capacity:Can be customized WhatsApp: 008618537181190

WhatsApp: 008618537181190

E-Mailggjx@gelgoog.com

E-Mailggjx@gelgoog.com Contact0086-18537181190

Contact0086-18537181190 Whatsapp0086-18537181190

Whatsapp0086-18537181190 TOP

TOP