Pineapple is a common tropical fruit with golden flesh, rich fragrance, sweet and sour taste, crisp and juicy, and is welcomed and loved by the public. The traditional dried pineapple is mainly dried by electric heating or dried in the sun, both methods have obvious shortcomings. GELGOOG offers heat pump drying equipment, which is designed with intelligent control, energy-saving and environmentally friendly, will become the first choice for drying pineapples and other fruits and vegetables.

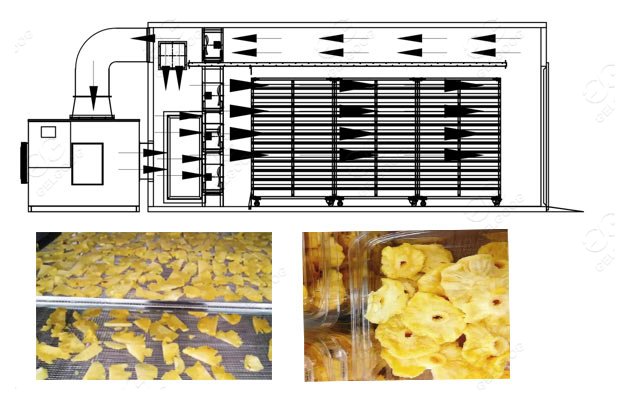

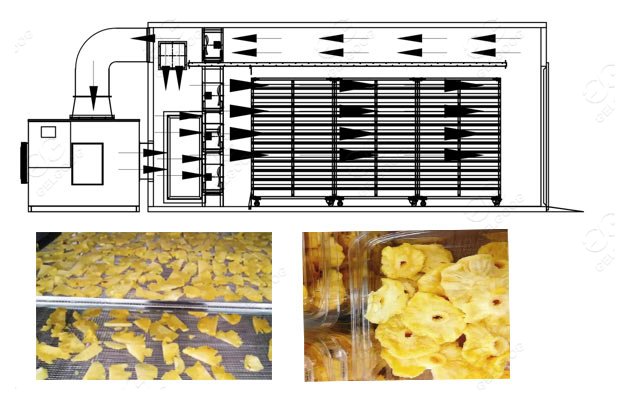

Production process of dried pineapple heat pump dryer:

1. Fruit processing

Choose eight mature pineapples, remove rotten fruit, diseased fruit, and insect fruit. Peel and remove the heart and eyes. The flesh has turned yellow, with pineapple aroma, and sliced. Each slice is 3-4 mm thick and fan-shaped.

2. Treatment of concentrated sugar liquid

Prepare 60% sucrose solution, that is, 100 kg of sugar solution contains 60 kg of granulated sugar and 40 kg of water. Dip the pineapple slices in 60% sugar solution, just after the sugar solution has soaked the raw materials, and the sugar soaking time is 24 hours.

3. Drying

Pick up the pineapple slices from the sugar solution, drain the water, and dry at 65°C for 18-20 hours until the water content reaches 16%, which is the standard. The drying process in the heat pump drying system is roughly divided into 5 drying stages

♥ The first stage: drying without dehumidification, the time is about 1.5 hours, the internal and external temperatures are the same, and the temperature is 50 degrees.

♥ The second stage: the temperature is 53 degrees, continuous dehumidification begins, and the dehumidification reaches 40%.

♥ The third stage: temperature 58 degrees, continuous dehumidification, humidity 26%.

♥ The fourth stage: temperature 55 degrees, humidity 20%, continuous dehumidification.

♥ The fifth stage: the temperature is 48 degrees, the humidity is 18%, the dehumidification is continuous for 1 hour, and the drying is completed.

The heat pump drying equipment is easy to operate and equipped with an LED display. During the drying process, the drying time is set. The operation interface of the display is clear at a glance. The temperature, humidity and the running status of each function in the drying room are displayed in real time, without personnel guards. When the time is up, the dried pineapple dryer automatically stops working.

The final dried pineapple chips will regain moisture directly in contact with the air, so they need to be sealed and packaged. If possible, vacuum packaging can be used to better preserve the color and fragrance of the pineapple chips.

Brand:GELGOOG

Brand:GELGOOG Capacity:Can be customized

Capacity:Can be customized WhatsApp: 008618537181190

WhatsApp: 008618537181190

E-Mailggjx@gelgoog.com

E-Mailggjx@gelgoog.com Contact0086-18537181190

Contact0086-18537181190 Whatsapp0086-18537181190

Whatsapp0086-18537181190 TOP

TOP