Your Position: Home > Products > Pastry Moulding Machines >

Brand:GELGOOG

Brand:GELGOOG Capacity:60K,100K,160K,200K pieces/8h, can be customized

Capacity:60K,100K,160K,200K pieces/8h, can be customized WhatsApp: 008618537181190

WhatsApp: 008618537181190

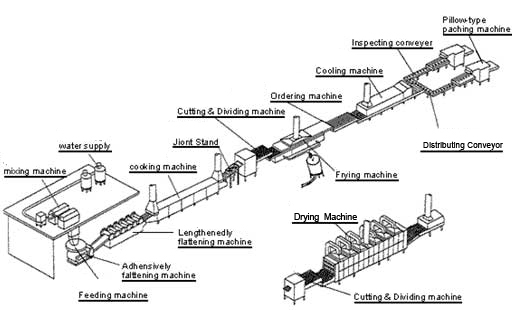

| No. | Machine Name | Model | Quantity | Note |

| 1 | Brine quantifier and mixer | GG10 | 1 SET |

Power:0.75KW,Volume:100L/SET The parts connect with water are made of stainless steel |

| 2 | Double speed dough mixer | GG200 | 1 SET |

Power 9/11 kw,200kg/pot/manual door opening The parts connect with flour are made of stainless steel |

| 3 | Disc cooker machine | GG200 | 1 SET |

Power:4kw,size of pan:Diameter1800mm*410mm The parts connect with flour are made of stainless steel (Make sure the flour after mixing can be absorbed and mixed well) |

| 4 | Composite and continuous dough pressing machine | GG7-50 | 1 SET |

Dough width 350mm,power 5.5kw+5.5kw=11kw 7 sets steel roller,frame is made of steel structure(frequency control) Diameter of roller:diameter 180*2,diameter 240*2,diameter180*2,diameter 162 |

| 5 | Single layer | GG50 | 1 SET |

16 meter,water sealing Main motor power 1.5kw(frequency control),Pan 0.37kw*2,stainless steel |

| 6 | Cutting,folding and conveying machine | GG80 | 1 SET | Main power 1.5kw+0.75kw,cutting blade 50 times/min,adjustable |

| 7 | Double layers drying machine | GG50 | 1 SET | Main motor power 1.5kw*2(frequency control+fan 5.5kw*4,net width: 2 meters,total length:30m), stainless steel net |

| 8 | Horizontal conveyor | GG63 | 1 SET | Main motor power 0.37kw |

| 9 | Cooling conveyor | GG63 | 1 SET | One horizental:0.55kw,fan 0.37kw*4 ,length:6 meters.width:0.50 meter ,Belt is made of stainless steel |

| 10 | Electricity control cabinet | GG-1 | 1 SET | Main program adopts frequency control ,PLC program control |

| Total | Total Power ~55kw |

E-Mailggjx@gelgoog.com

E-Mailggjx@gelgoog.com Contact0086-18537181190

Contact0086-18537181190 Whatsapp0086-18537181190

Whatsapp0086-18537181190 TOP

TOP