Fruit & Vegetable Machine

- Automatic Garlic Root Concave Cutter Machine

-

- MOQ: 1 set/Sets

- Brand:GELGOOG

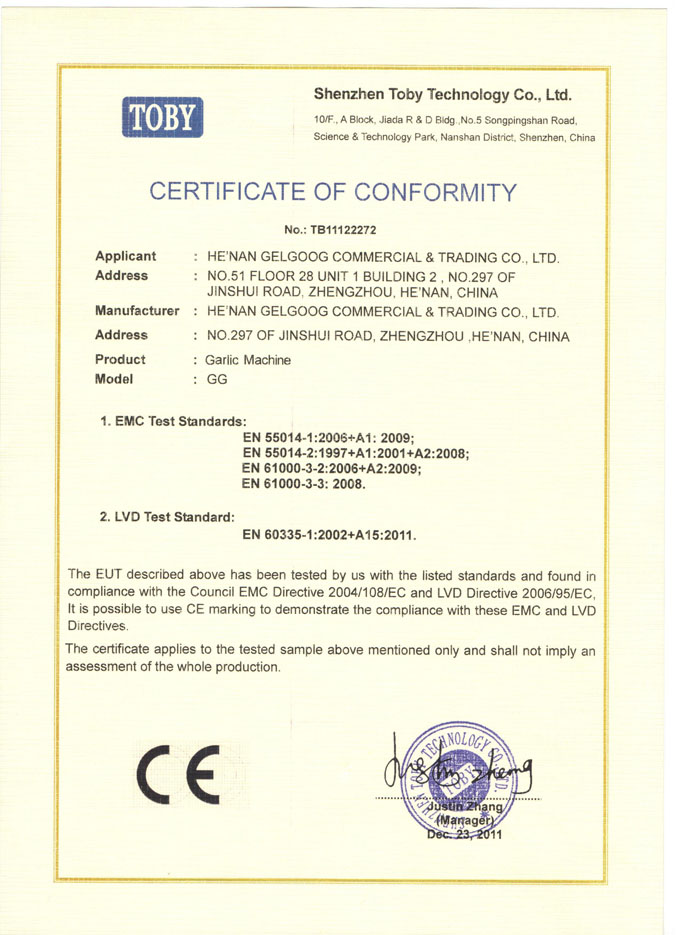

- Certification:CE

- Supply Ability: 100 sets per monthSet/Sets Per Month

- PAY METHOD:WEST UNION L/C T/T CASH

- Warranty Time:6 Months

- LOADING PORT:Qingdao Port/Tianjin Port

- Country Of Origin:China

- Features

- Technical Data

- FAQ

- Case

- Certification

Automatic Garlic Root Concave Cutting Machine

It used to cut both dry and wet garlic root concavely,capacity is between 400-500kg/h,stainless steel body means the machine is durable and high-quality.

The machine use the special high speed cutting tool, the blade is not fever of garlic without damage, cut after the garlic root assumes the circular arc concave position, and small amount of resection and resection clean, completely removing the human use of fox cutter and other cutting machinery waste is big, efficiency is slow

The machine use the special high speed cutting tool, the blade is not fever of garlic without damage, cut after the garlic root assumes the circular arc concave position, and small amount of resection and resection clean, completely removing the human use of fox cutter and other cutting machinery waste is big, efficiency is slow

Working process:

1.artificial garlic will be placed upside down one by one to rapid operation of conveyor belt, conveyor belt to carry garlic to floating cutting, cutting and quickly remove garlic root.

2.cut the size of the root control:

Blade regulator is designed on the machine, as long as the regulator of the blades according to the requirements of the cutting root size adjustment, the machine can be automatic control in the process of cutting roots resection.

| Model | Voltage | Power | Capacity | Dimension | Weight |

| GGDQ-2 | 220V/380v | 1.5kw | 400-500kg/h | 2250*800*1320mm | 185kg |

1.Ask:The raw material of the machine?

Answer:This machine made of stainless steel 304.

2.Ask:Which the function of this machine?

2.Ask:Which the function of this machine?

Answer:It used for cutting the root of the garlic with the concave type.

3.Ask:What is your packing method?

3.Ask:What is your packing method?

Answer:All of our machine will be packed with wooden packaging as export standard.

4.Ask:How long of the stock up period?

4.Ask:How long of the stock up period?

Answer:This machine with the stock up period is 7 working days.

Brand:Zillow realer estate

Country:Germany