Fruit & Vegetable Machine

- Multifunctional Grain Peeler Machine

-

- MOQ: 1 set/Sets

- Brand:GELGOOG

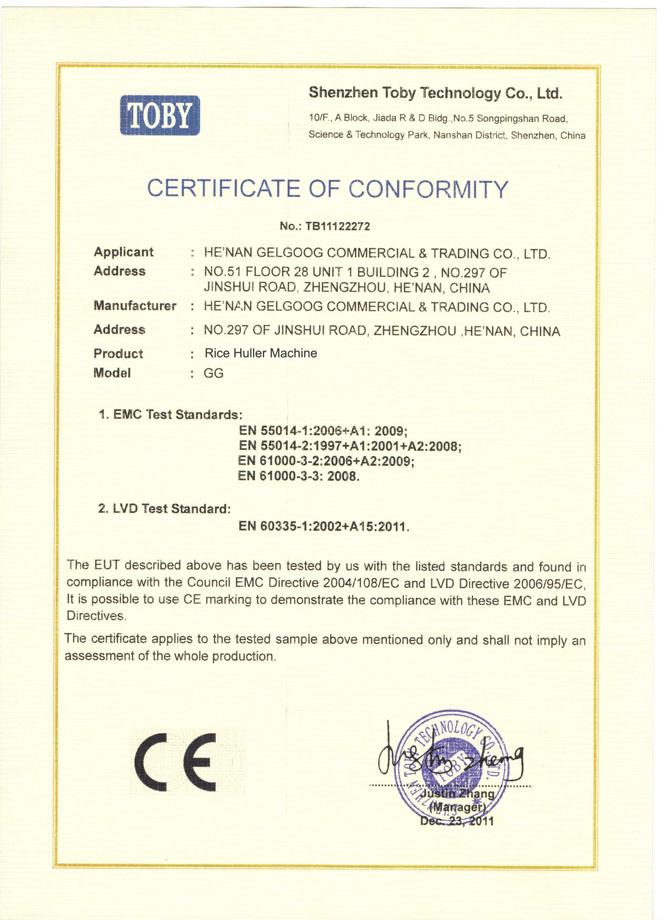

- Certification:CE

- Supply Ability: 100 sets per monthSet/Sets Per Month

- PAY METHOD:WEST UNION L/C T/T CASH

- Warranty Time:6 Months

- LOADING PORT:Qingdao Port/Tianjin Port

- Country Of Origin:China

- Features

- Technical Data

- FAQ

- Case

- Certification

Multifunctional Grain Peeling Machine is used for peeling kinds of grain,such as wheat,barley,soybean,mung bean,maize etc.Widely used and high peeling rate.

This machine is easy to operate,and simple construction,and with low price. It can separate the husk automatically.The grinding wheel and screening is easy to change it is the standard parts.

Therefore,it is suitable for the wheat,beans and corn peeling. It can single work,or make into unit to operate.

1.The raw material flow on the surface of the rotating grinding wheel evenly by action of gravity,the pushing board can throw them into the space,which between grinding wheel and circular conical surface,the raw material will grind in the space until the husk was separated.

2.Some of the husk can be sucked by the fan from the sieve mesh and expell through engineer body, the rest husk will be sucked by the airflow of the expell part,when it out in the outlet,and the finished product will flow on the bottom of the expelling board,and pushed out.

3.The rate of the peeling rate is depend on the hardness of the grinding wheel,number of the revolution,the size of the space( between gringding wheel and circular conical surface),pressure and resistance. The pressure can be adjusted by the flow of the exit and change the length of the pushing board.The resistance can be adjusted by the place of the knife. The effect of the expelling husk can be achieved by change the airflow of the expell part(adjust the place of the regulation).

| Model | Capacity | Dimension | Power | Weight |

| GG-200 | 150-200kg/h | 720*320*950mm | 2kw | 60kg |

| GG-330 | 300-400kg/h | 900*520*950mm | 7.5kw | 130kg |

| GG-900 | 500-700kg/h | 900*600*950mm | 11kw | 140kg |

1.Ask:Which grain can be processed by this machine?

Answer:Wheat,barley,soybean,mung bean,maize etc

2.Ask:What is the advantage of this machine?

Answer:Widely used,and the machine with two discharge holes,so the kernel and the shell out of this machine respectively.

3.Ask:What are the vulnerable parts of the machine?

Answer:The screen is the vulnerable part of the machine,so we will send another screen free.

4.Ask:How long of the stock up period?

Answer:Usually,our stock up period is 7 working days.

Brand:Zillow real estate

Country:Germany